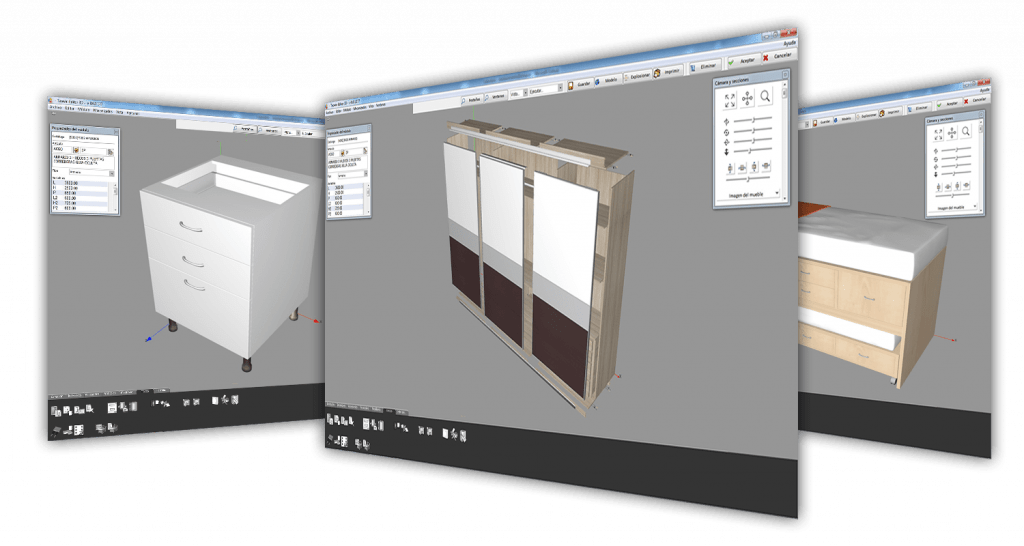

Just like Teowin Manufacturing, Teowin ERP displays your pieces of furniture in 3D, turning them into dynamic objects, with the potential to integrate infinite properties (measurements, colours, cuttings, etc.). However, it also edits all technical and commercial documentation necessary to develop a new product.

Conceive your furniture catalogue from A to Z, for selling as well as manufacturing.

Teowin ERP offers two different ways of managing order entries. You can not only automatically import projects created with Teowin Design into your dashboard or your order backlog, but also manually, thanks to a specific tool designed to make the process agile.

Manage order entries manually or automatically, connecting Teowin's modules together.

Upon order registration, Teowin Manufacturing automatically calculates the material supply and plans all the tasks to be carried out during production. The software also issues all the necessary reports to ensure the proper running of the factory. Finally, it connects to the machines in order to automate manufacturing processes (cutting, edge banding, machining, assembly, etc.).

Control work stations, plan production tasks and automate the machine connections.

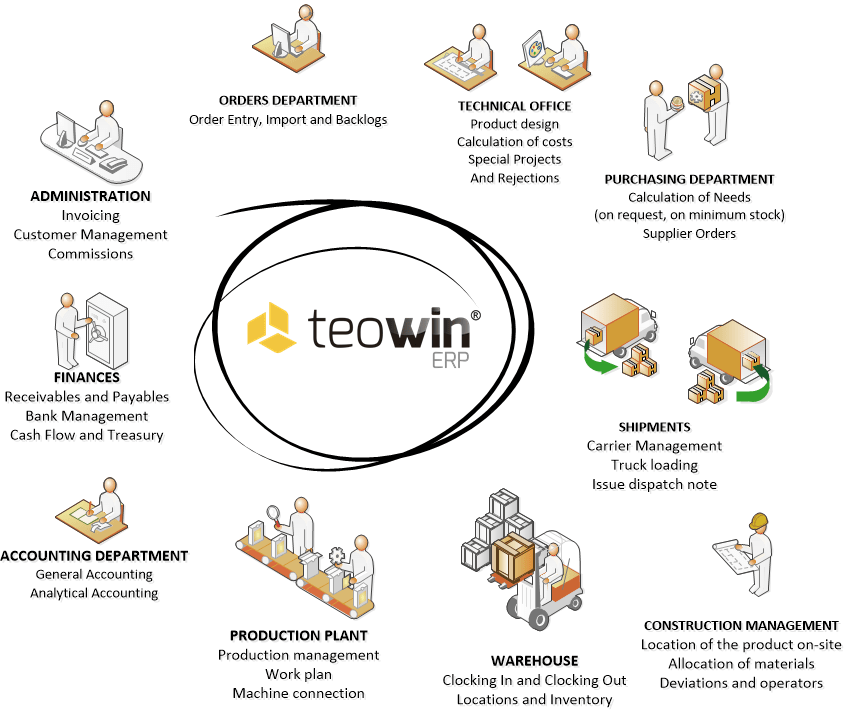

What makes Teowin ERP different from Teowin Manufacturing is its ability to edit all necessary information to run a furniture factory. Clocking staff entry and exit and parts marking in the workshop enable you to assess the operator employee productivity and the system efficiency. It also allows you to verify that the orders being prepared or in production will be delivered on time.

Control employee attendance and simplify data collection throughout the factory.

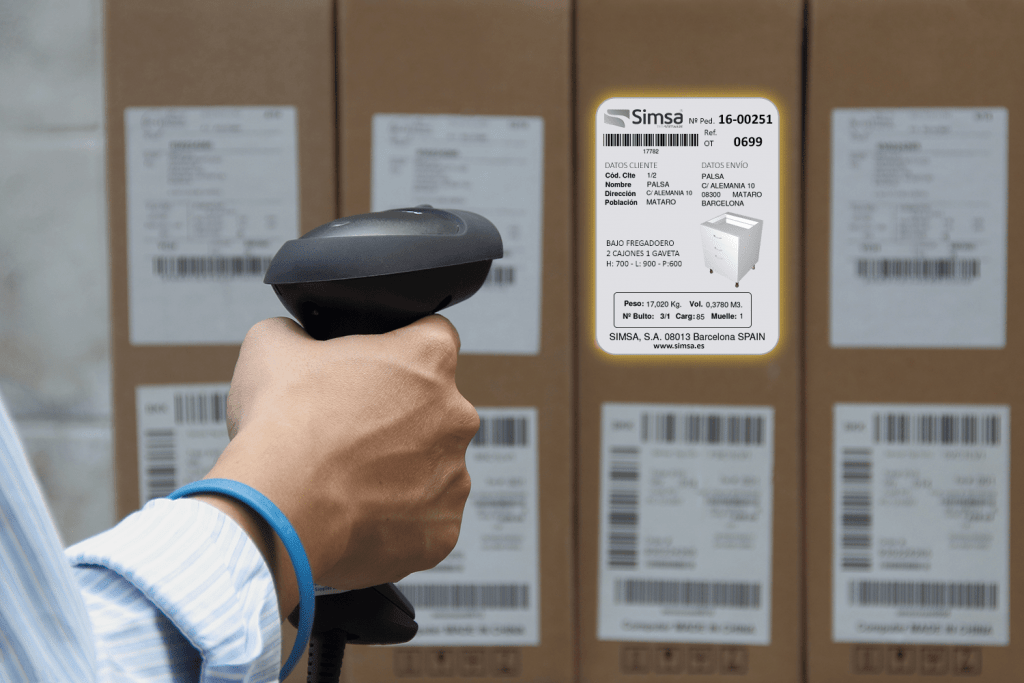

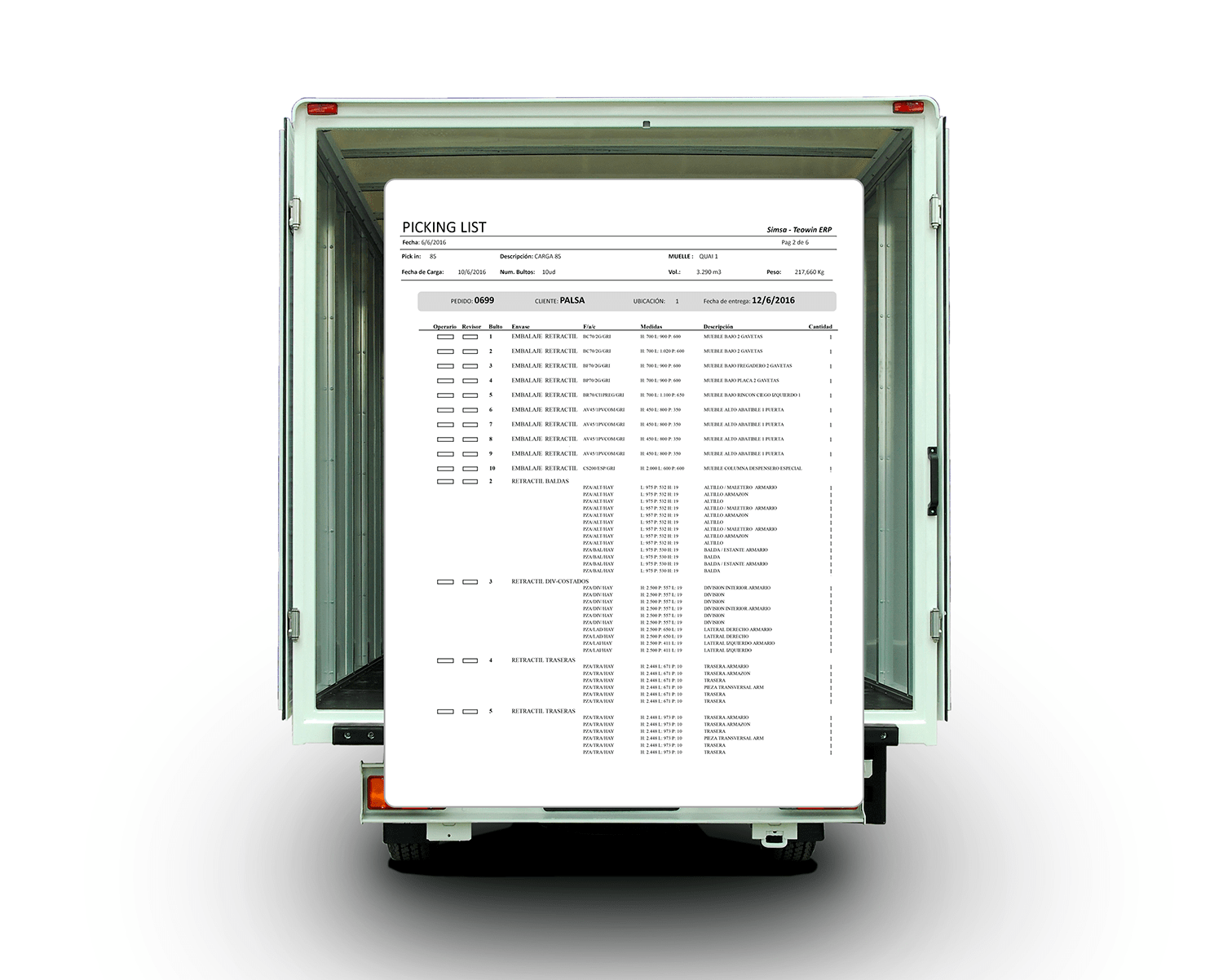

When managing a factory, it is critical to control all the materials needed in the manufacturing process. It is vital to know what is required and where to locate it at all times. Teowin ERP inventory management feature classifies all the materials (raw materials, semi-finished products and end-products) and delivers all this information through picking-list and packing-list reports. The software also enables you to control the truck loading for the end-product dispatch.

Organise incoming and outgoing materials, whether raw materials, semi-finished products or end-products.

The Commercial Management module is another important solution. Its main purpose is to manage everything related to customers and suppliers. Functions include quality control for reception or rejection of materials, but it is also linked to the calculation of purchasing needs and automatically generates orders to suppliers according to the manufacturing and stock criteria applied in the factory (just in time, overstock or combined). It also makes business results easier to interpret thanks to its summaries and statistics.

It calculates the purchasing needs and controls dispatch and loading.

Teowin ERP includes other key factory management modules, such as Project Design, Outsourcing Management, Construction Management, CRM, Treasury and Accounting, etc.

Available modules include financial and accounting management, construction sites management, CRM, outsourcing, etc.

Observe Teowin's agility in each of its facets (3D design, BOM drafting, and special furniture items manufacturing : discover its many features and advantages.

Visualise all the services included in our technical support to ensure success for your software deployment. Start using it today!

Discover the new version of Teowin 11.0, including the export module to the new graphic engine allowing to navigate in real time, always with high-quality renders.